Key Takeaways

In the grand tradition of Henry Ford and Bell Labs, manufacturers are using cutting-edge AI tools to automate tasks, predict disruptions and make new discoveries.

Three case studies: a design software firm helps users build AI-powered digital twins; a high-tech manufacturer leverages AI to build specialty electronics for clients; and an internet giant uses AI to discover previously unknown materials for building new technologies.

In the search for tomorrow’s manufacturing leaders, we look for firms that are embracing AI to uncover patterns in complex and interwoven sets of data, unlocking new efficiencies.

While ChatGPT captured the public’s imagination, the staid manufacturing sector was already putting AI to work – potentially reaping more benefits than any other sector, according to McKinsey. Find out how tapping AI is a natural step in the evolution of industrial automation.

In the news: AI is transforming industrial automation

Manufacturers have long used automation to improve operational efficiency, decrease defects, reduce factory downtime and maximize productivity. Decades ago, research and development companies such as Bell Labs—and trailblazing individuals such as Henry Ford—were on the cutting edge. More recently, 3D printing, robotics and computer vision have helped upgrade production methods across many industries—from aerospace to metals & mining. Today, artificial intelligence (AI) is leading the way, with digital twins, generative AI and other technologies transforming industrial automation in ways Henry Ford could never have imagined. Here are three notable examples.

Case studies: Using AI in new ways to aid manufacturing and material discovery

A design software provider (“DSP”) offers proprietary digital twin software1

DSP built advanced software to help organizations create and operate digital twins in real time. (A digital twin is a virtual replica of a physical object, operation or process, frequently powered by AI and continuously updated with a steady flow of data.) Many organizations already use DSP’s existing 3D software solutions to design products, buildings and manufacturing processes, so the new digital twin software is a natural fit. DSP’s AI-powered simulations help solve issues early, and help operators better manage product lifecycles and improve on subsequent iterations. Automated factory production lines have already been built with input from DSP’s digital twin software, and we see many more applications across industries—from automotive to food production to retail.

A manufacturing services company (“MSC”) leans into AI2

MSC is an electronics manufacturing services company that helps customers design and build electronics products. Among MSC’s many innovations are the AI- and machine learning based detection systems used on the company’s factory floors. The systems help identify defects quickly and accurately, saving costs and enhancing efficiency—and they get more intelligent over time. The company also uses AI to optimize production processes, reducing redundancies and improving throughput. MSC even helped design an automated barista system that uses AI to serve coffee and cocktails.

A large internet company (“LIC”) uses AI to discover millions of new materials for high-tech manufacturing3

Researchers at LIC used AI to discover 2.2 million new crystal structures, including an estimated 380,000 that are sufficiently stable for synthesis and further research. This significantly expands the number of known stable inorganic materials by nearly tenfold. In the past, materials scientists identified new crystals through a time-consuming trial-and-error process. The announcement demonstrates how AI can significantly accelerate the discovery process for new materials, which can be a key enabler of the next hardware or industrial breakthrough.

Why it matters

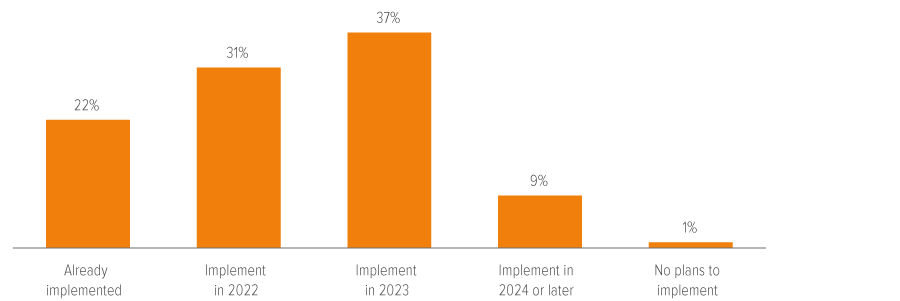

Today, industrial manufacturing is undergoing a sea change powered by AI innovations. Not only do most companies already recognize AI’s potential to improve their operations (Exhibit 1), but the evidence shows that it’s working. A recent survey by McKinsey suggested that manufacturing is the function that may be poised to reap the biggest benefits from AI adoption. Of the hundreds of organizations actively using AI, 55% anticipated at least a 10% decrease in manufacturing costs, while 66% expected at least a 5% increase in manufacturing revenue.4

The case studies above show the power that innovative use of AI can bring to a manufacturing process, but also the substantial front-end work needed to make these systems successful. They also showcase how AI impacts much more than just the tech industry. At Voya IM, we believe that AI is arguably the most transformational technology of our time, with the potential to reshape industries of every stripe. The companies that effectively use AI to transform their businesses will likely be in the best position to gain market share and deliver higher levels of profitability. In the industrial manufacturing space, we look for firms that are embracing AI to uncover patterns in complex and interwoven sets of data, unlocking new efficiencies. These are the companies that may be able to develop more effective models for automating tasks, improving forecasts, reducing errors and predicting disruptions.

Source: “2022 State of Connected Operations Report,” Lawless Research, commissioned by Samsara, May 2022.